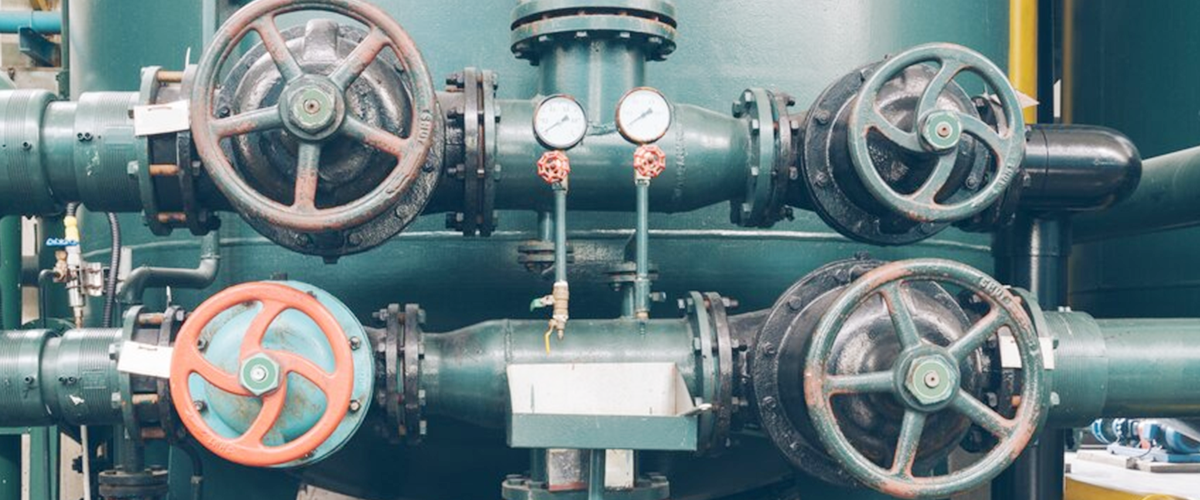

Overview of Pipeline Systems

The Pipeline systems are the backbone of many industrial operations, responsible for the transport of liquids, gases, and other substances across various industries.

Materials

Each material used in pipelines, such as Stainless Steel (SS), Galvanized Iron (GI), Mild Steel (MS), UPVC, CPVC, and PVC, comes with its own set of advantages, application areas, and specific engineering requirements.

Stainless Steel (SS)

Galvanized Iron (GI)

Mild Steel (MS)

UPVC (Unplasticized Polyvinyl Chloride)

CPVC (Chlorinated Polyvinyl Chloride)

PVC (Polyvinyl Chloride)

Engineering Codes and Standards for Pipeline Construction

Our pipeline projects comply with a range of globally recognized engineering codes and standards, ensuring quality, safety, and reliability.