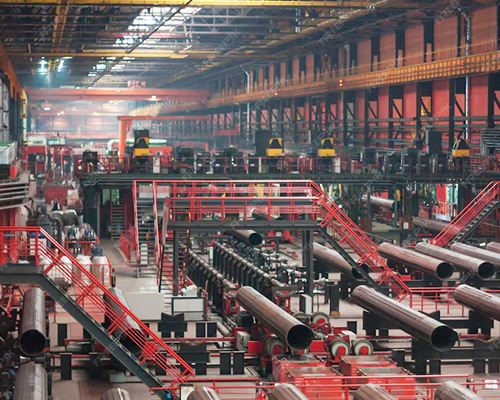

Principles of Steel & Pipeline Manufacturing

At our core, we transform steel into innovative designs that push the boundaries of engineering. Through cutting-edge technology and creative solutions, we craft precision-driven structures that redefine industry standards. Every project reflects our commitment to excellence, where ideas turn into tangible, lasting innovations.

Key Operations in Steel & Pipeline Manufacturing

At our core, we transform steel into innovative designs that push the boundaries of engineering. Through cutting-edge technology and creative solutions, we craft precision-driven structures that redefine industry standards. Every project reflects our commitment to excellence, where ideas turn into tangible, lasting innovations.

Raw Material Processing

Casting & Rolling

Heat Treatment & Surface Coating

Welding & Fabrication

Testing & Inspection

Logistics & Supply Chain

A. Steel Industry Segments

B. Pipeline Industry Segments

Greenfield Project Execution for Steel & Pipeline Manufacturing

With expertise in Greenfield and Brownfield projects, we ensure all facets of oil and gas manufacturing, pipeline solutions, and infrastructure development are executed to the highest standards.